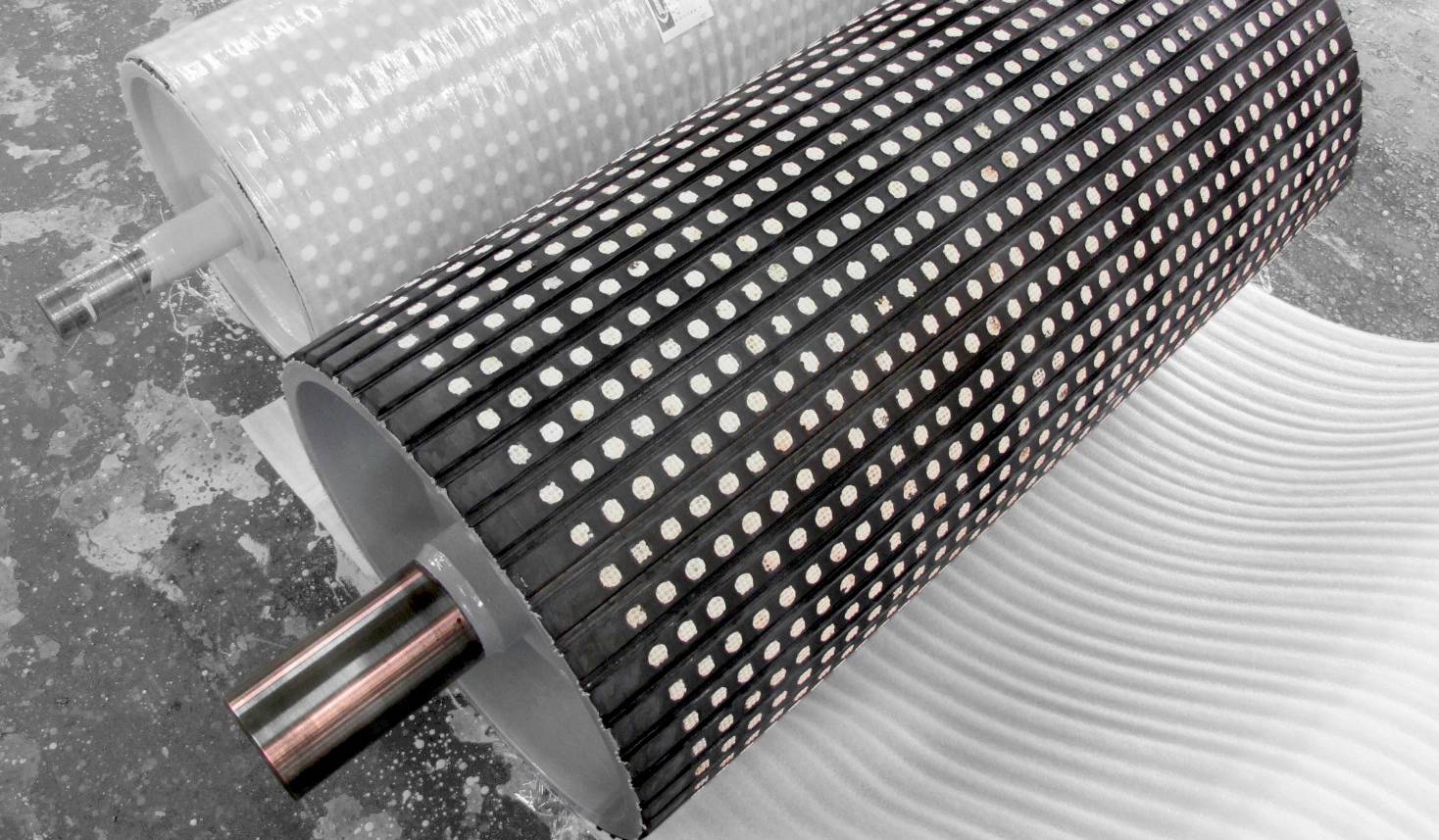

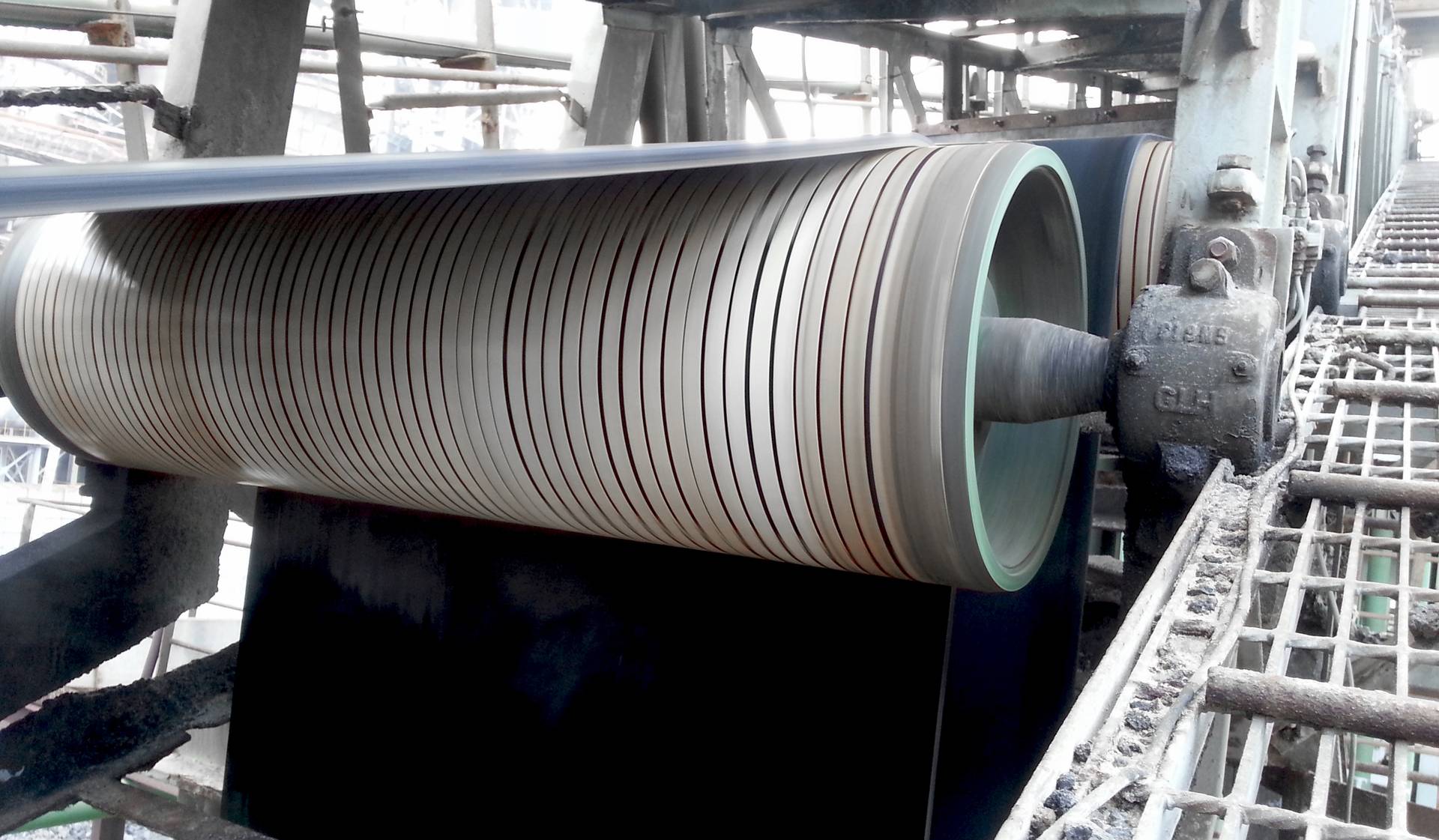

Ceramic Pulley Lagging

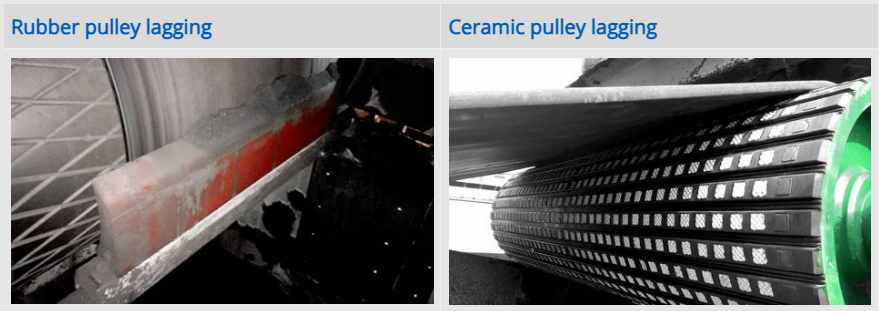

WHEN CONVENTIONAL RUBBER LAGGING FAILS TO CORRECT BELT SLIPPAGE AND WEARS PREMATURELY, JIMWAY’S CERAMIC PULLEY LAGGING PROVIDES A COST EFFECTIVE SOLUTION THAT ENSURES OPTIMUM TRACTION OF DRIVE PULLEYS UNDER WET AND SLIPPERY CONDITIONS.

Reduced the conveyor belt’s wear and slippage with Jimway’s ceramic pulley lagging system, which not only increase uptime, but also dissipate water and residue via dewatering grooves. In addition, it serves as a maintenance free wear resistant cover; meanwhile, it also creates maximum traction, without the associated damage to belts. There are constructed of abrasion resistant square or round ceramic to control slippage and increase conveyor belt traction.