Features/Advantages

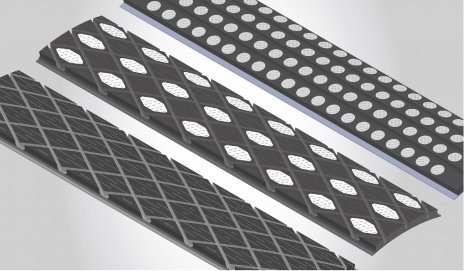

Ceramic replaceable pulley lagging

- Fitting perfectly on the curved surface (Round tiles)

- Quick replacement on site

- Extremely high friction coefficient

- Less system downtime

- Lifetime extension

- Less material buildup

Rubber replaceable pulley lagging

- Fitting perfectly on the curved surface

- Quick replacement

- Less system downtime

- Lifetime extension

- Less material buildup

Raised rubber retainer

- Improving carryback

- Reducing the vibration of the cleaner’s blade and noise

- Improvement of belt cleaner performance