Features/Advantages

Quick info

| Standard | JIS/CEMA/DIN/ISO or customiziation |

| Bearing | 6204~6308 2RS |

| Pipe OD. | Ø89.1~Ø159mm |

| Shaft OD | Ø20~Ø35 |

| Size | Be customized |

Shaft

- CNC machined and diameter tolerance:JIS h7

Bearing

- The lubrication of 2RS deep groove ball bearings with NTN,SKF,FAG ,and C&U brand for reducing friction between parts during relative movement to ensure the bearing effective operation even temperature rise

Bearing housings

- CNC machined and bearing housing seat tolerance:JIS N7

Labyrinth seals

- Less deformation due to good compressibility and resilience

- Grease-filled labyrinth seal

- Dust,water ,and pollution sources prevention

- Effective operation in a wide temperature range

Grease

- Non-rubbing,protecting for bearing,and saving power due to good quality greases for two particular temperature range (-20°C~+65°C, -40°C~+65°C)

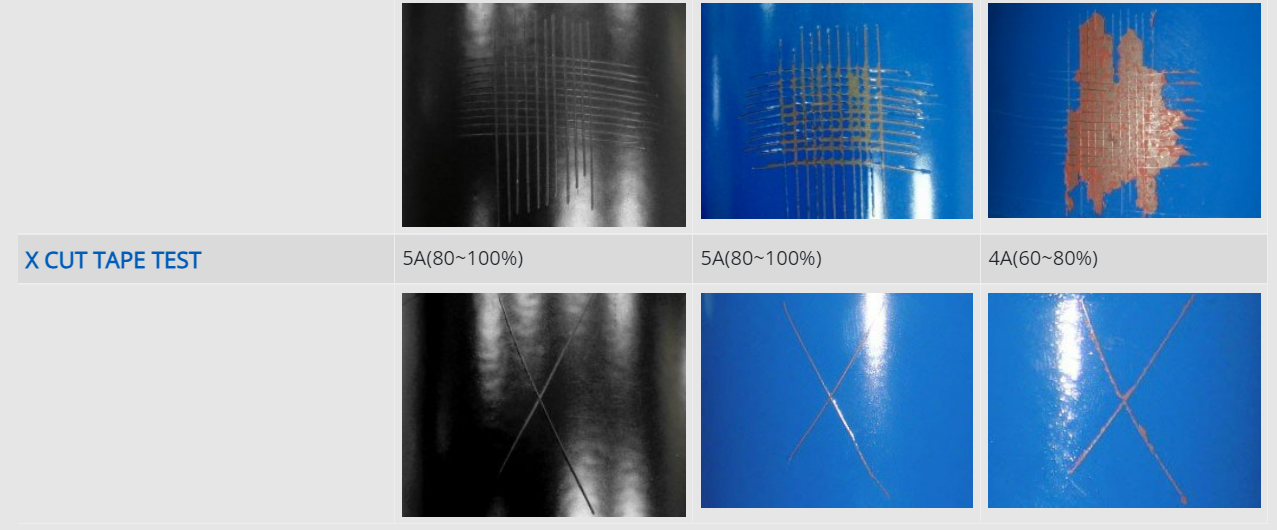

Powder coating

- One of the most environment-friendly coating ststems to coat in the range of 50~300um per one cycle.Powder coating with good impact resistance not easily rubbed off when handling the roller.

- Removing rust and degreasing parts before powder coating for effective operation and the belt service life extension.