Features/Advantages

Quick info

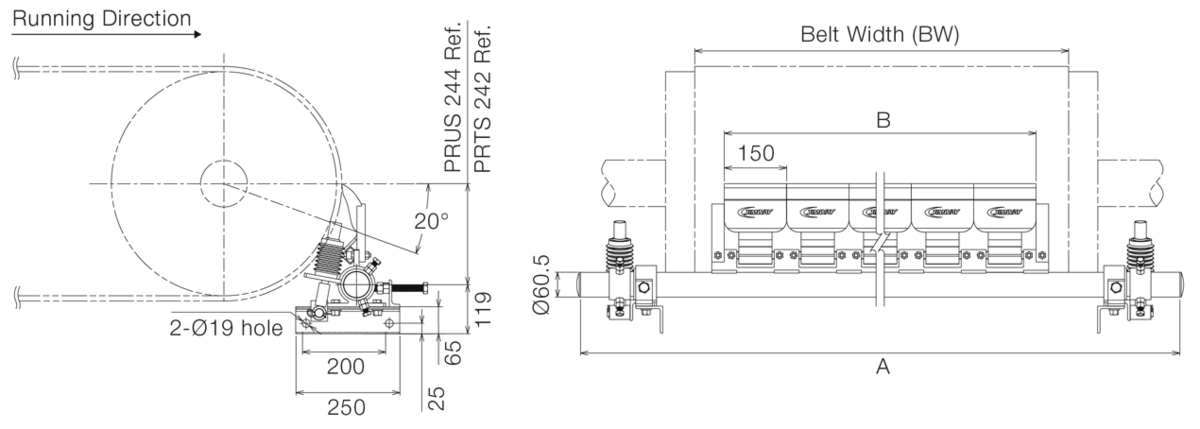

| Belt width | 600~2000mm [24″~78″] |

| Belt speed | ≤4m/s |

| Cleaning direction | One direction only |

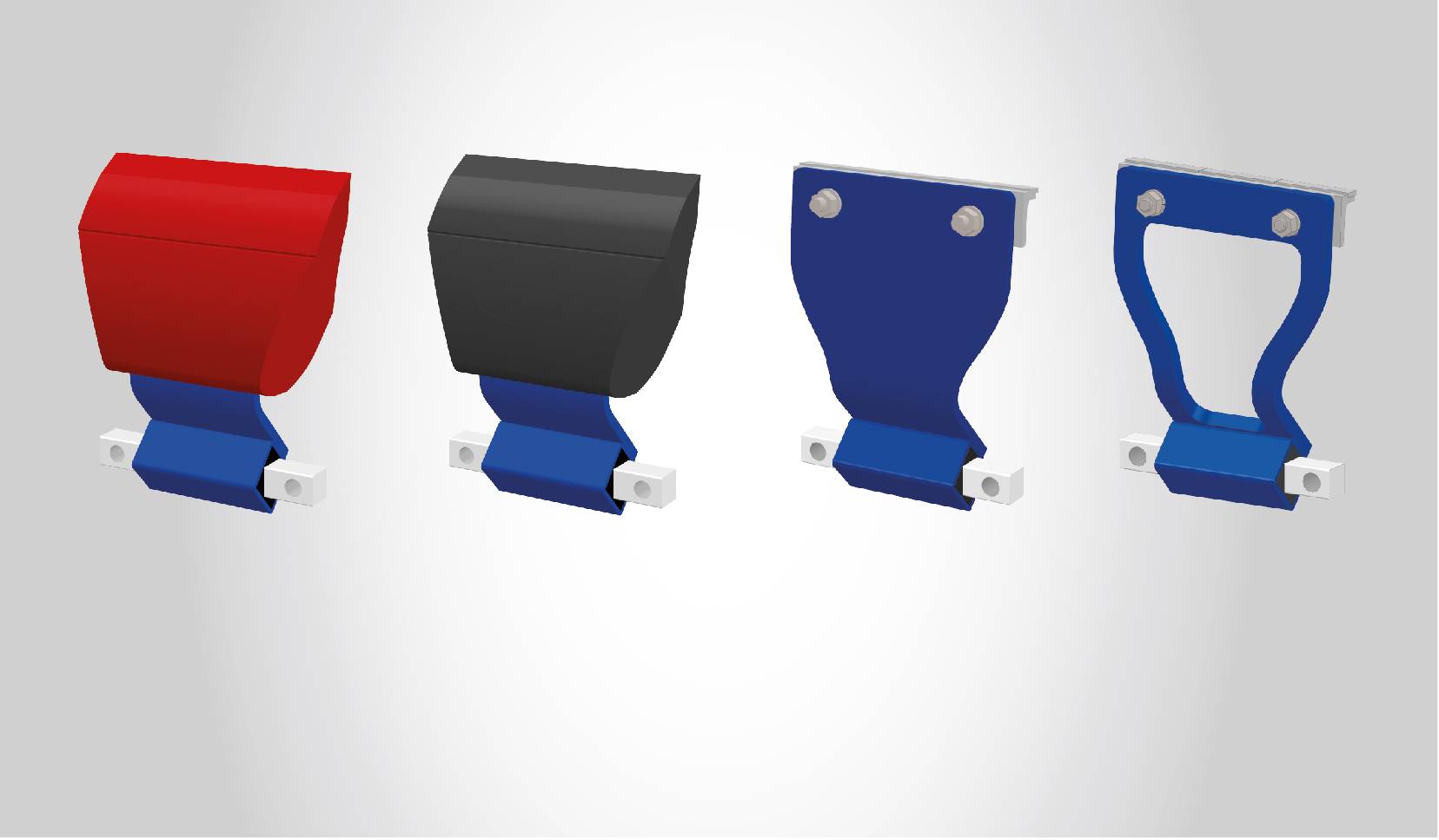

| Material selection of blades | PU(PRUS) / nano(PRNS) / tungsten carbide(PRTS, PRHS) |

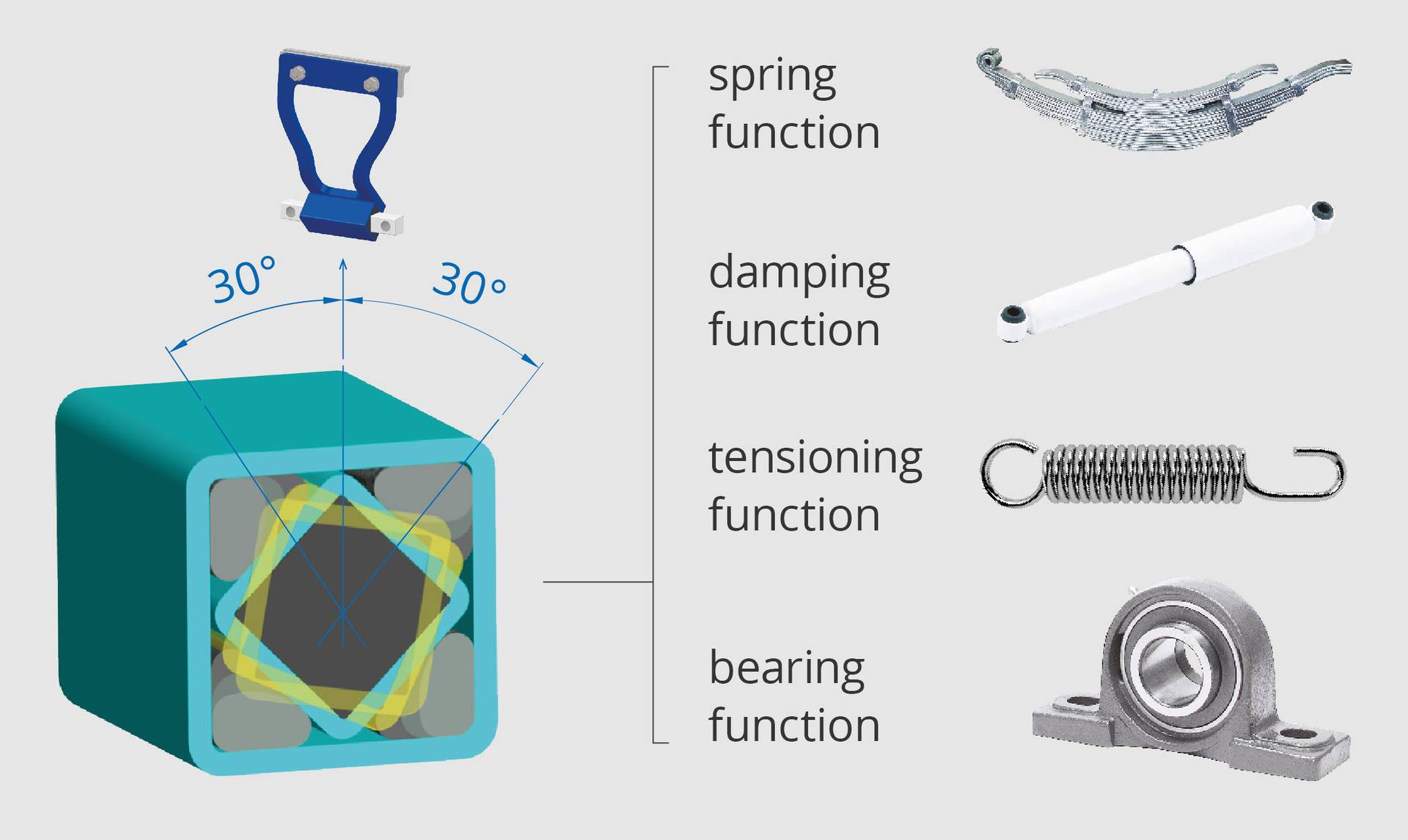

Excellent elasticity torsion element

- Absorbing vibration and noise

- High-performance

- Used on spliced belts (PRUS)

- Maintaining blade-to-belt contact

- Self-adjust blade

- Belt-friendly

Easy to install and maintain

- Simplicity and economy of use

Easy visual tension check