Features/Advantages

Quick info

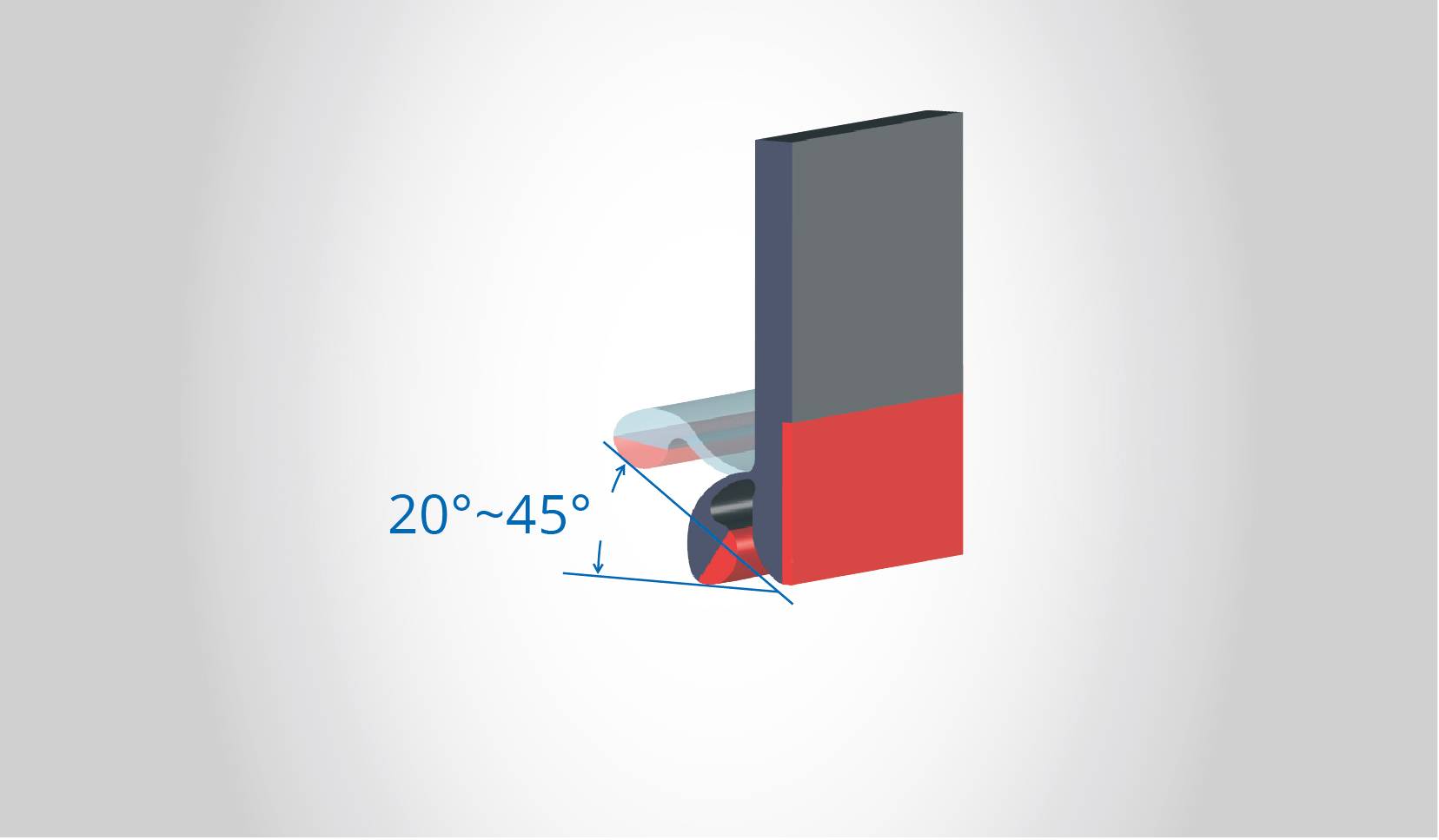

| The angle of the 2nd layer | 20°~45° |

| Standard spec. | H:120/150/200mm, t: 12/15mm |

| Non-standard spec. | H:100/180/250/300mm, t:10/20mm |

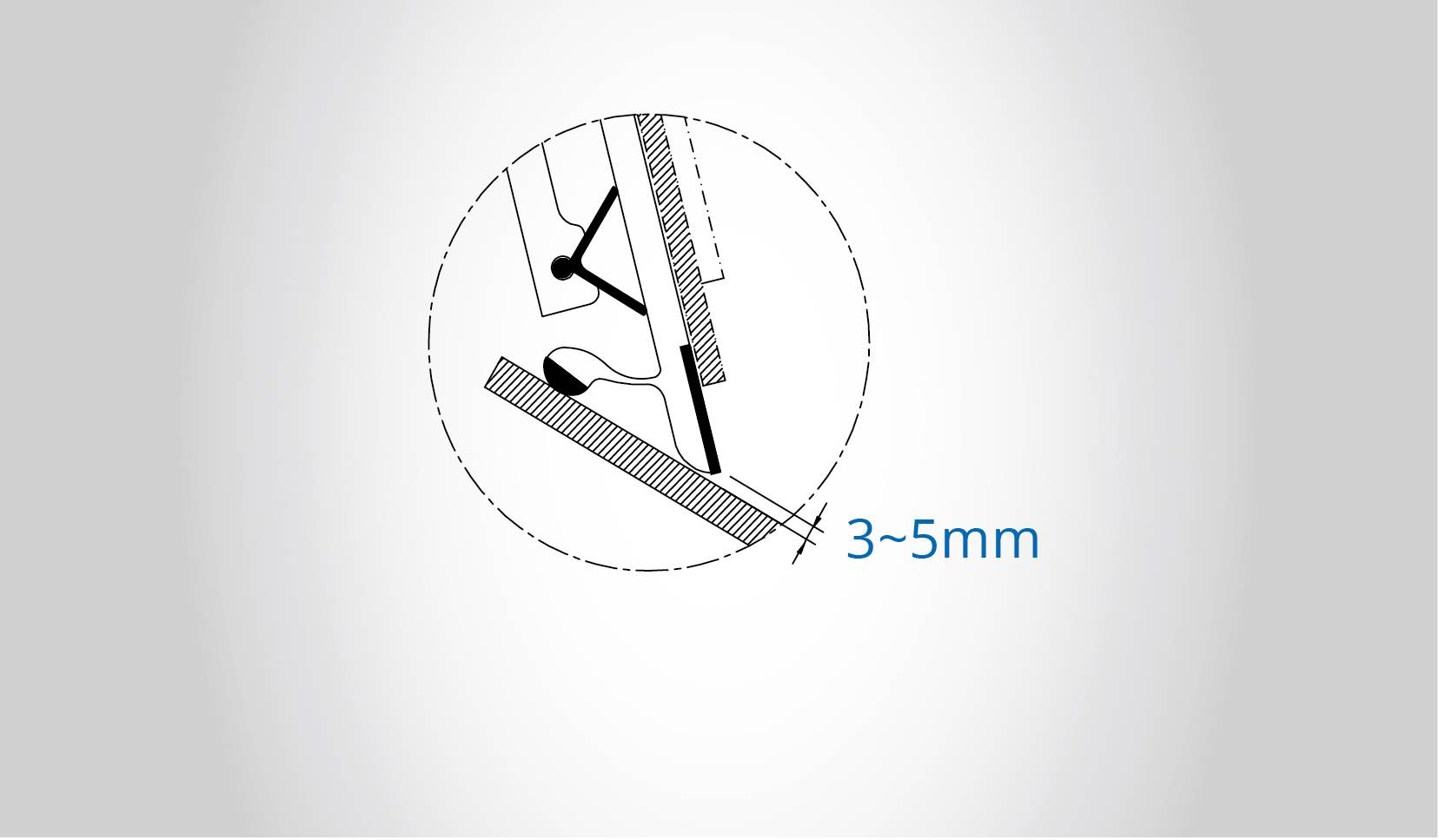

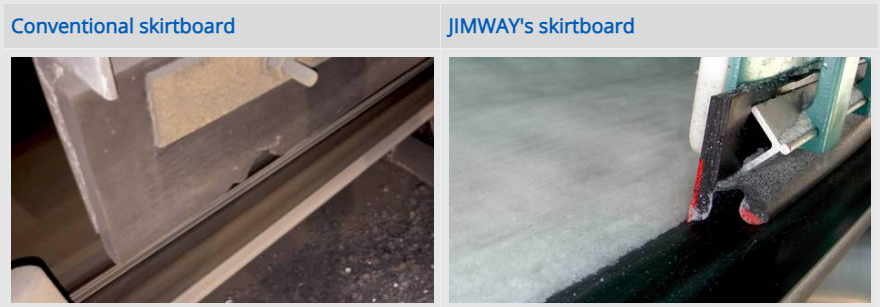

Dual-sealing design

- The 1st layer: prevent material spillage

- The 2nd layer: prevent dust leakage

Two layer bi-material design

- Red: 55mm height with PU surface

- Black: SBR rubber

- Extending service life of skirtboard

Less downtime

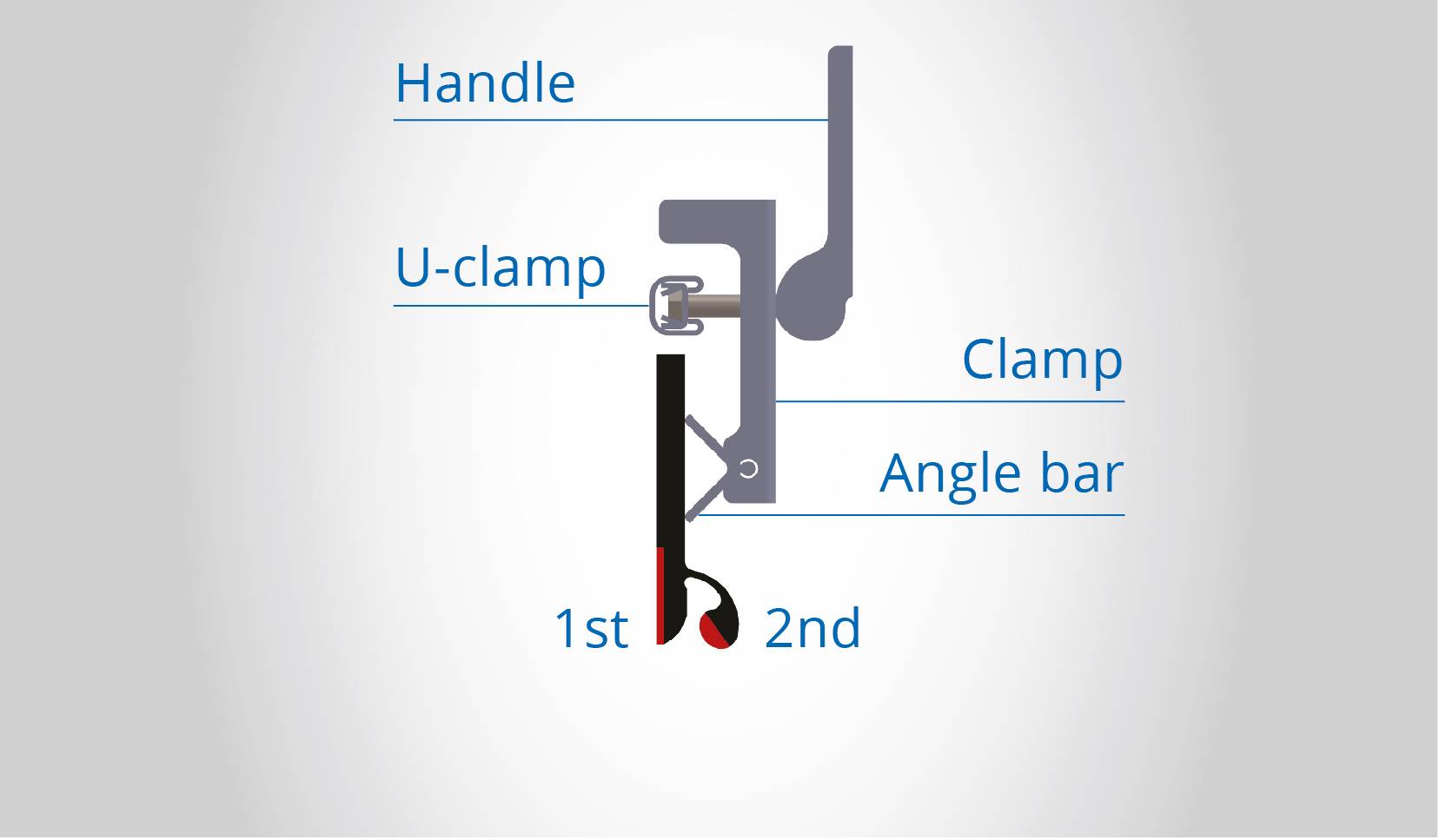

- Easy and fast installation

- No tools needed for installing

- Held in place by clamp

- Welded a U-clamp on the skirtboard per 500mm without dislodging

Less clean-up costs

- Less meterial loss and pollution