Features/Advantages

Quick info

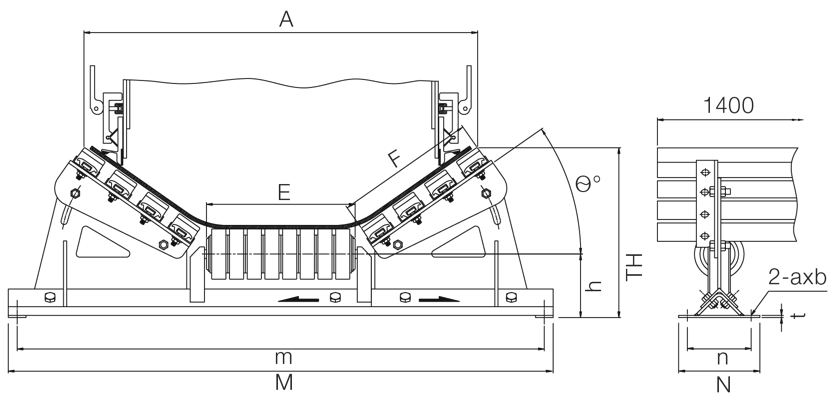

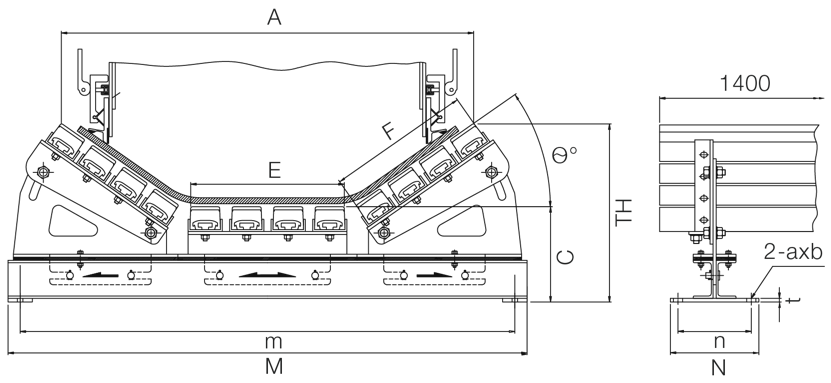

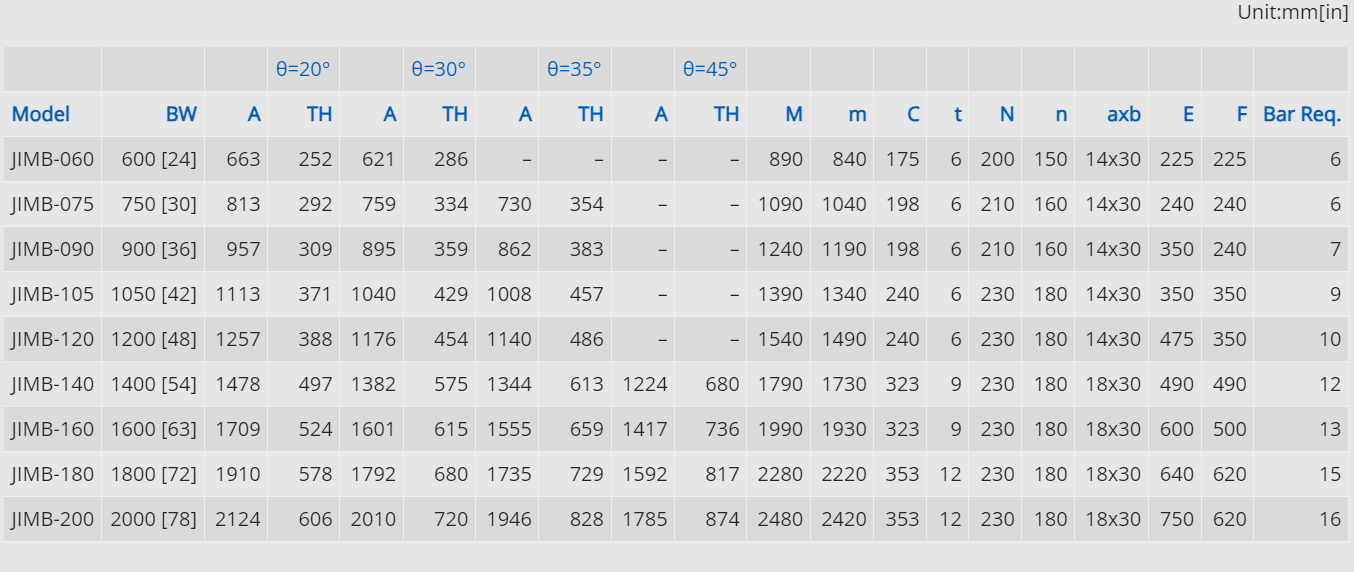

| Belt width | 600~2000mm [24″~78″] |

| Adjustable trough angle | 20°/30°/35°/45° |

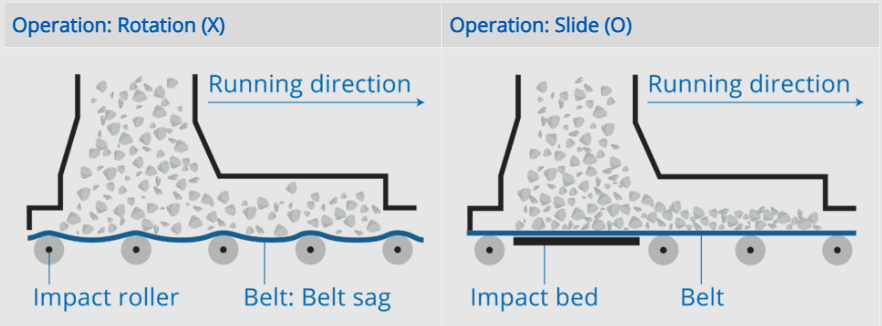

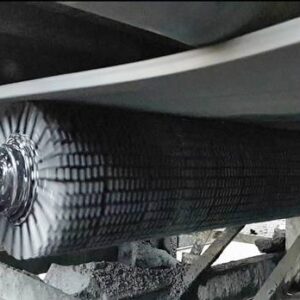

Spills and leaks control

- Less belt vibration

- Low impact energy

- Adjustable trough angle of tile frames

- Ensuring the impact bar completely contacts the belt

Less downtime

- An easy and safe slide sideways out of the supporting arms/frames without raising the belt

- Quick-change Rollers/bars

Belt-friendly